Rising damp signs, causes and treatment

Rising damp occurs when groundwater rises through capillaries in masonry to saturate it. To prevent this, modern homes are built with a DPC (Damp-Proof Course).

Compared to penetrating damp or dampness caused by excess condensation, rising damp is relatively rare.

In older buildings over 100 years, it is often caused by a faulty or missing DPC.

In newer buildings, rising damp is often caused by adjoining structures that introduce moisture above the DPC.

This guide will help you to accurately identify rising damp and successfully treat it.

- Rising damp in walls

- Internal signs of rising damp

- External signs of rising damp

- What causes rising damp?

- How does rising damp in houses occur?

- How to treat rising damp

- Is rising damp real?

- Using an electrical moisture meter

- How to repair rising damp

- How to treat rising damp

Rising damp in walls

Rising Dampness on Interior Walls

Rising dampness on interior walls can lead to unsightly efflorescence, peeling of wallpaper, blistering and mould on internal walls. This is not only unpleasant to look at, it can also cause severe health problems. The easiest way to deal with rising damp on interior walls is to treat the dampness with Dryrod Damp-Proofing Rods and refurbish interior walls using the Dryzone Express Replastering System. This system allows for a treatment of the rising damp and a subsequent refurbishment of interior walls in as little as 24 hours.

Rising Dampness on Exterior Walls

Rising dampness on exterior walls can cause building damage, such as the degradation of render, efflorescence, and cracks in masonry. In order to eliminate rising damp on exterior walls, treatment with either Dryrod Damp-Proofing Rods or Dryzone Damp-Proofing Cream is recommended. These treatments stop rising damp from further affecting walls.

Internal signs of rising damp

Dampness in walls originates from a variety of different sources. It is therefore important to find out exactly where the dampness comes from to save time and money on the wrong treatment.

Internally, rising damp will tend to display as a tide mark of dampness, plaster or paint damage on the wall. This usually presents around 1m up from the ground floor. This is the point where the capillaries in the brick cease moving moisture upwards due to gravity and natural evaporation.

Some other signs of rising damp are obvious:

Decaying skirting boards or timber

Efflorescence on interior walls

Visible damp patches on walls

Black, green and white mould growth

Wallpaper and paint peeling and blistering

External signs of rising damp

Rising damp can often be seen on exterior walls too.

Efflorescence on exterior walls

Discolouration on exterior Walls

Corrosion of bricks and mortar

Rising damp in concrete floors

Groundwater not only rises through capillaries in walls. It can also rise through concrete floors. When rising damp occurs in concrete floors, a remedial solution for damp-proofing solid floors needs to be found. Safeguard offers multiple solutions for waterproofing concrete floors in buildings.

Rising damp and mould

Black mould is not necessarily associated with rising damp. All types of damp can cause mould growth.

As mould growth can occur due to a number of different reasons, the source must be thoroughly investigated to avoid unnecessary treatments and time investment.

Frequently Asked Questions

-

What happens if rising damp is left untreated?

Rising damp causes catastrophic damage to the fabric of your home. Moisture from rising damp destroys wallpaper, plaster and eventually brick and masonry. Dampness encourages black mould growth. Rising damp can spread to adjoining timber, causing wet and dry rot. Homes will be difficult to sell or remortgage with an active rising damp problem. -

Is rising damp a serious problem?

Rising damp is always a serious problem. As the source of moisture is the ground itself, rising damp will only worsen without remedial action. Even if the damage is minimal and ignorable now, it will only worsen. -

Can rising damp be fixed?

Yes! Correct diagnosis is the key to the installation of a new damp-proof course. A new damp-proof course combined with replastering the damaged walls is a very effective way of fixing rising damp. However, a new DPC is not always necessary. Always ensure no adjoining structures bridge the existing DPC. -

What are signs of rising damp?

Rising damp internal signs include:- Efflorescent salts at ground level on external walls

- Damp sections of wall

- Flaking or bubbling plaster

- A stale, mouldy, musty smell

- a damp tide mark around 1m up the wall

Rising damp external signs include:- Rusting metal fastenings

- Efflorescent salts on brick walls

- Spalling bricks and mortar

- A damp patch rising from the ground

-

Will a dehumidifier help with rising damp?

Dehumidifiers reduce humidity levels by drawing in moisture from the air. They can be used as part of a condensation minimisation strategy but will not help stop rising damp. They may mask the problem by dealing with the symptoms (dampness in the home), but they will not stop it from occurring. -

What is the best way to treat rising damp?

To install the most accurately dosed damp-proofing course, use Dryrod Damp-Proofing Rods. Unlike competing injection creams, each Dryrod is dosed with 100% silane/siloxane for the most effective barrier to dampness. Simply drill holes and push the rods into the mortar course. The liquid diffuses deeply throughout the wall without waste.

What causes rising damp?

Rising damp is often the cause of structural damage in buildings. Internally rising groundwater saturates walls and pollutants. Saltpetre, which is contained in water, damages building materials. With time, constant dampness in walls can lead to mould, blistering, the peeling of paint and wallpaper and damaged render.

In older buildings, this type of damp is often caused by a damaged DPC or the lack thereof. Relevant building regulations for damp-proof courses were developed in the early 1900’s. However, these were not always adhered to. As a result, some of these DPCs become damaged over time.

How does rising damp in houses occur?

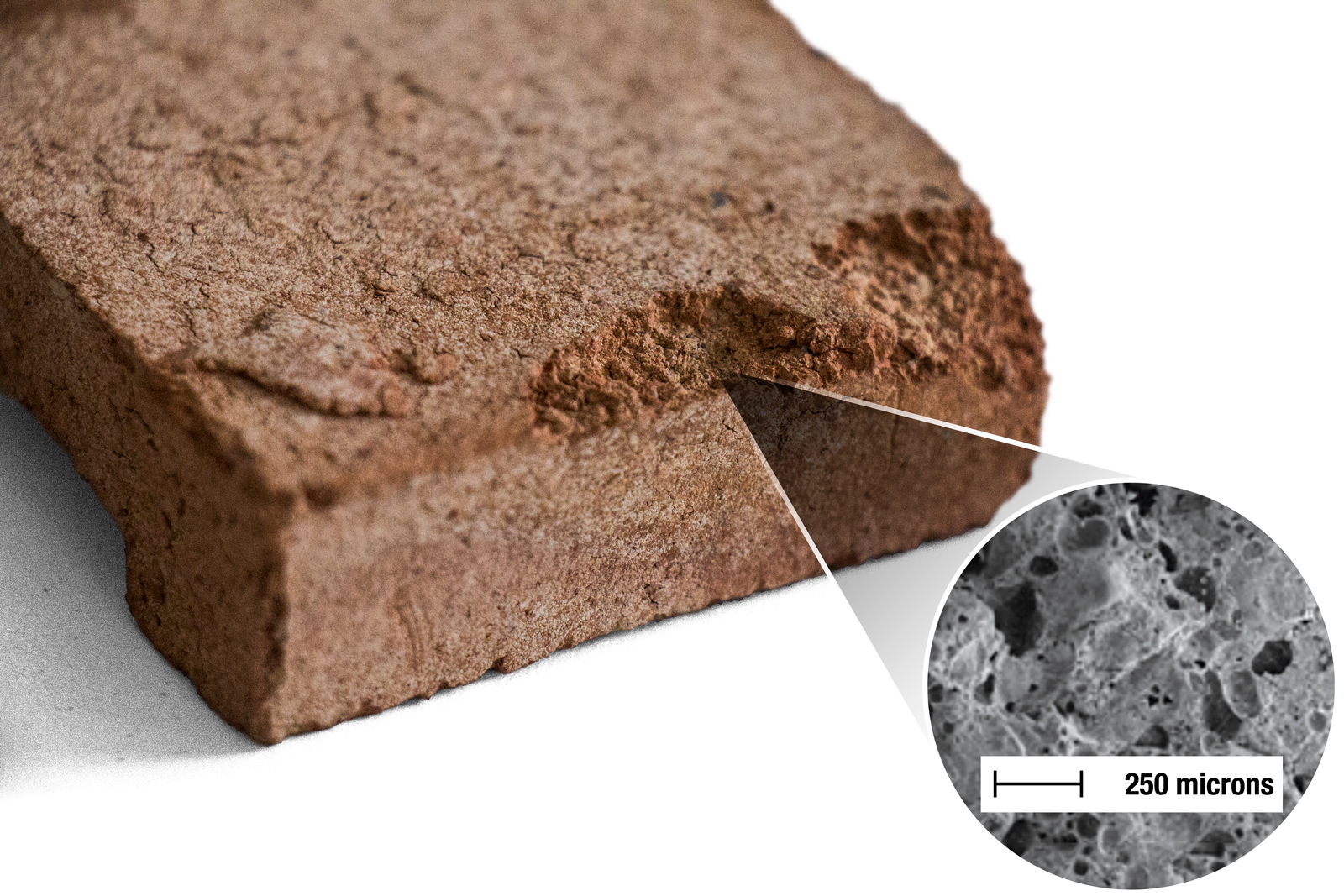

Rising damp in walls (also known as capillary ascending moisture) is the ascent of moisture through capillaries in masonry.

Capillaries are tiny and very thin tubes. In masonry, these tubes are of varying thicknesses. In some cases, they form cavities. The smaller the diameter of the capillary, the stronger the surface tension.

When moisture enters these capillaries, surface tension causes it to rise through them. The smaller the capillaries, the higher moisture travels.

Capillary action is found in nature to distribute moisture throughout plants.

It is also used in medicine. To take a small blood sample, a very fine tube is held against a small cut. Capillary action draws the blood up into the small tube.

Masonry contains fine piliform (hair-like) tubes. As a result, capillary action in masonry is strong. Moisture can quickly saturate a brick wall and travel up to 1.5 metres from the source. This is how rising damp sets in.

Is Rising Damp real?

At its simplest, rising damp can be easily proven by sitting a brick in a shallow pool of water and watching it rise!

Negative press coverage of failed and unnecessary installations has led to widespread misconceptions about rising damp.

Rising damp is rare in newer homes and more common in homes over a hundred years old. It is most common when moisture rises through a wall…

- with a damaged damp-proof course

- without a damp-proof course

- through a wall where the ground level is now higher than the installed damp-proof course.

- through a wall with non-damp resistant plaster or other building materials that “bridge” the installed damp-proof course

Remember – if the source of moisture is not the ground, it is not rising damp.

As rising damp can be misdiagnosed, a commonly held opinion is that rising damp is a myth. You may hear that rising damp problems did not exist historically or that it is a UK-centric problem, but this is simply not true.

Building regulations worldwide specify damp-proof courses. Cases of rising damp have been thoroughly documented throughout history. Vitruvius first documented rising damp in Italy around 30 BCE. He even specified the first damp-proof course: a layer of mortar and burnt brick render laid 3 feet above ground level.

Rising damp is the rarest type of damp problem because there’s only one cause of rising damp – groundwater.

The source of dampness should always be thoroughly investigated. An incorrect rising damp diagnosis can lead to further damage and unnecessary costs. If in doubt, always consult an expert. Remember – condensation and penetrating damp are also potential causes of dampness.

Using an electrical moisture meter

A full survey with an electrical moisture meter can be undertaken to find symptoms of dampness in walls.

Although electrical moisture meters cannot be used to measure exact moisture content, moisture meter readings can help establish a “moisture profile” to establish the pattern of dampness along walls.

Helpful guidelines and common moisture profiles can be found in our handbook Rising Damp & its Control.

How to treat rising damp

To stop rising damp in walls, a remedial DPC needs to be installed. Since 2000, the most popular and effective method for installing a new damp-proof course is Dryzone Damp-Proofing Cream – a fast, uncomplicated and effective way of stopping rising damp at its source.

The Dryzone System is a complete rising damp renovation range. It features two options for treatment, two replastering options for repairing affected walls and a mould-resistant paint for protecting walls from further damp-related problems.

Rising damp prevention

To prevent rising damp from damaging walls, modern houses are built with physical DPCs. In older houses, physical DPCs can become damaged over time, installed improperly or bridged by adjoining works.

When houses are modernised or extended, building works affect built-in physical DPCs. Ground level changes can bridge the physical DPC layer to cause rising damp. A remedial DPC must be installed to prevent rising damp from recurring in these instances.

Repairing surfaces damaged by rising damp

Rising damp damages plaster, wallpaper, paints and skirting boards. Before internal wall repair begins, the source of the problem must be treated. Following the installation of a working DPC, the wall will start to dry out.

However, efflorescent salts can form on the surface of plaster to damage it. If salts form under the plaster surface, it can crumble and blister.

Replastering walls is an important part of an overall rising damp treatment. Keep in mind, some plasters, such as Gypsum, are not compatible with salt-contaminated walls. Salts traces from internal walls can migrate to a new coat of plaster and dampness may persist.

For a replastering system designed to be used after rising damp treatment, check out the Dryzone range of damp-resistant plasters.

Treating rising damp on internal walls

Before internal wall treatment can begin, all skirting boards around the affected area must be removed. Additionally, all salt-contaminated plaster needs to be hacked off to a minimum of 300 mm above the last detectable signs of dampness or salt contamination.

Once the brickwork has been exposed, rising damp itself can be treated. By using Dryzone Damp-Proof Injection Cream or Dryrod Damp-Proofing Rods, a remedial DPC can be injected directly into the masonry to ensure a targeted treatment of the problem.

Regardless of whether Dryzone or Dryrods are used, holes must be drilled into the lowest accessible mortar course that is still at least 150 mm above the exterior ground level. These are typically drilled at regular intervals of 120 mm, with a diameter of 12 mm [1]. Injecting a damp-proof cream or inserting damp-proofing rods ensures a targeted and highly effective treatment of rising damp.

The first step to stop rising damp with Dryzone Damp-Proofing Cream is to drill holes at a regular interval into the lowest accessible mortar course [1]. Next, Dryzone is injected into each drill-hole. The holes are then sealed off with an appropriate mortar.

Dryrod Damp-Proofing Rods are the latest and most effective way to stop rising damp. Dryrods are pre-dosed fibre rods, which are simply inserted into the mortar course [2]. No spillage and no need for specialist tools.